The therapeutic effects of natural hot springs on sore muscles and joints was revered long before 1956, the year Candido Jacuzzi developed a special water pump to give his arthritic nephew Kenneth more regular water treatment at home. In that year, the home hydrotherapy industry was born. Backyard hot tubs for recreational use became readily available to Canadians in the 1970s, and grew more and more popular throughout the 1980s and 90s. At the start of the new millennium, the hot tub product category split to include swim spas which are larger units that can more easily accommodate a full body workout.

One Canadian company Hydropool Hot Tubs corporation has an international reputation for innovative design, high console functionality and gorgeous finishes.

Joel Levy and I were invited to the Hydropool showroom to shoot product shots of their next generation hot tubs and swim spas. When nobody was looking we persuaded a floor manager to give us a little tour of the factory and together we saw with our own cameras just how their award-winning hot tubs and swim spas are manufactured.

Because their state-of-the-art factory is brimming with trade secrets, our handler was keen to keep our exploration as brief as possible. He got real nervous any time either Joel or I stepped off the yellow line that bisects the assembly plant. Our spontaneous photo safari started in the vacuum forming dept at the far east side of the factory, beside the main loading dock.

Every Hydropool hot tub and swim spa unit for sale in the showroom today started life back here as a special type of plastic called rigid acrylic. Older people working in the trades might call this Acrylic Glass, and its more scientifically known as poly(methyl methacrylate), or what my high school shop teacher called Plexiglas or Perspex® which is a brand name. These are cast acrylic sheets, a transparent or translucent thermoplastic. Every part of a modern hot tub has evolved in the last couple decades, and the plastic surface is no exception. The material now comes in every colour imaginable and in faux marble and many lovely granite patterns too.

As we watched a large white sheet of rigid acrylic was placed into a steel frame with strong clamps on all sides to hold it like a drum head. The frame was shuffled left into an oven enclosure where it was rapidly heated with gas elements above and below. When the white acrylic sheet started to sag and droop in the center, the operator knew it was pliable enough to perfectly conform to the mold. With another touch of a button he turned off the stove and swung the hot plastic sheet back out into the open and over top of a giant box that was a swim spa mold.

The frame was lowered and the malleable plastic sheet was then sucked down over the mold. All the air between the hot plastic and the mold’s many contours was extracted through tiny pin holes until the soft sheet perfectly filled all the pattern’s many crevices and shelves. There was a collective ‘aha’ moment as frame was unclamped. and suddenly we did behold a beautiful smooth finished, inverted, swim spa interior plastic shell.

We followed the newly formed shell to a nearby cooling area where exhaust fans blew cold air and we were told how, in this climate, the plastic hardens in just a couple of minutes. This half egg is the upside down top surface of a swim spa.

Inside this shell is the smooth finished surface where people will someday sit and swim. At this point however, it must be greatly strengthened to hold the weight and pressure of the immense amount of water it will soon contain. This is done by adding four coats of fiberglass and resin to its backside.

In the 1970’s, when hot tubs were just starting to get popular, and when manufacturers were just starting to build these assembly lines, the fiberglass and resin coating dept was the bottleneck that jammed up the whole factory. This is still the longest and most arduous part of the assembly process but advanced technology and new products and procedures have greatly improved the situation. The work that used to take days can be done in a few hours now and much more safely. Workers used to have to lay thin strips of spun glass onto the back of the plastic shell and painstakingly ‘paint’ them into place using big gooey resin coated paintbrushes and brooms. Now the workers have blow guns which apply chopped up fiberglass cord directly onto the unit. This fluffy fiber coating is followed by a resin coat, and once that’s rolled into place and dried they do it again, and again. They do it four times in total to build up the tough outer wall required to hold the immense water pressure inside the tub. When this process is complete they apply a thin insulating foam coat to the back which is also a vapour sealant for the fiberglass and resin.

Next the spa-to-be is moved along the assembly line to a trimming station where workers polish away rough edges and cut the prescribed holes for the water drains, and turbines and the dozens of air jets in each tub.

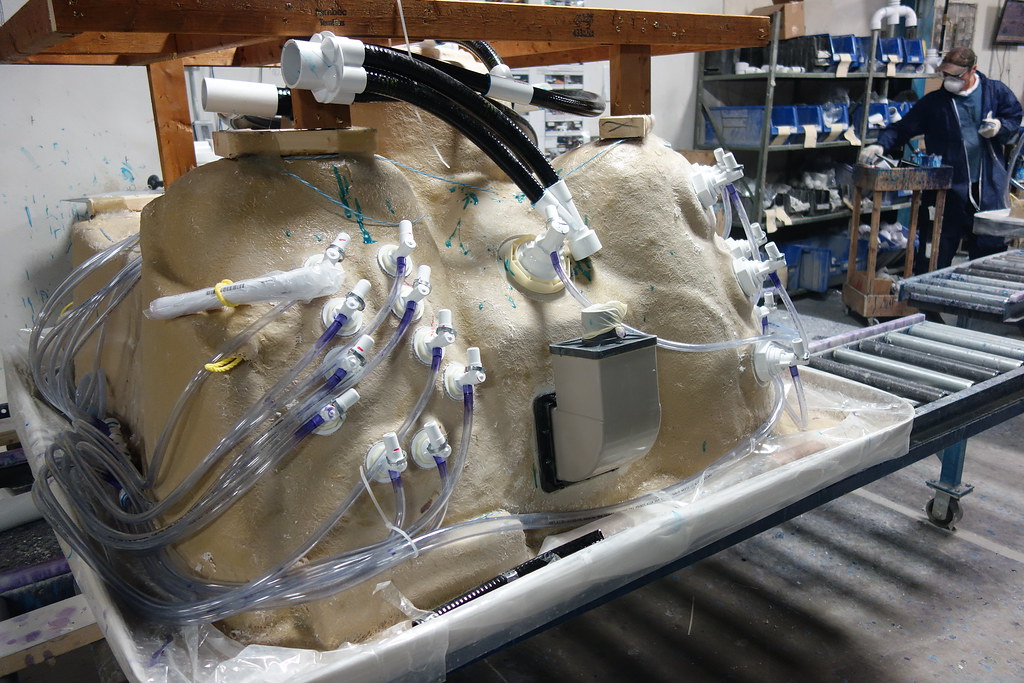

The cutters know each tub design by heart of course, but if they become confused they can look for the nipples left by the mold. They cut around the nipples and leave dozens of four inch wide holes in the side of the tub. These holes are filled at the next station with thick plastic cups sporting metal nozzles. These cups are glued into place and the piping for these jets is connected at the next station.

Clear tubing is generally used for air while other colours of hose have different functions. There’s between twelve to fifteen meters of hose in every hot tub, and double that in a Hydropool brand swim spa.

Once the hot tub is fully piped and each tube inspected and tested for leaks, the unit is finally flipped over and the top coat examined for cracks or any other damage that may have occurred in the factory up to this point. Once the floor manager is satisfied with each unit’s integrity, each freshly piped tub is made ready for installation into its prescribed wooden frame.

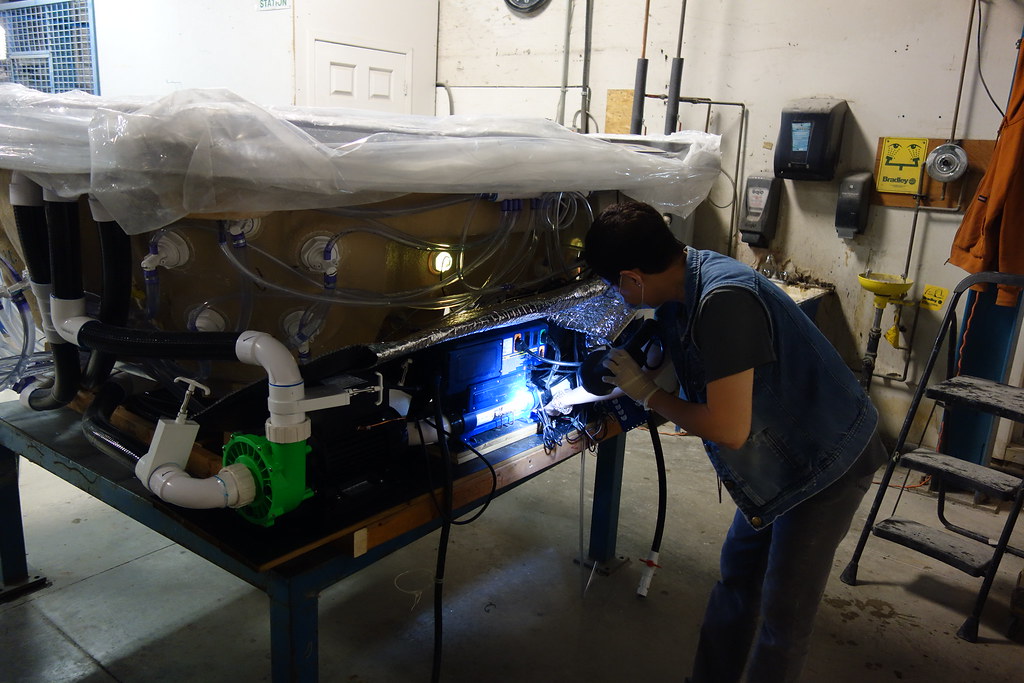

Next the body and the brains of the hot tub come together for the first time as the motors and pumps are installed and connected to the electronic console. After testing the unit’s basic functionality, the other electronics are loaded into the cabinets. These added features could include stereo speakers and LED lights and even a pop up or built-in flat screen television set. These amenities are installed as specified and connected to the motherboard with all wiring fed through another colour tubing.

At the end of the line, each hot tub and swim spa produced at the Hydropool plant is mercilessly tested, inspected and then tested again at a different station for a different reason under different conditions.

Before being boxed up and shipped out to consumers, a master technician puts the hot tub through all console settings and inspects the entire system to make sure every nozzle is performing as required. He tests everything you can imagine and things you’d never think of..

At the end of the tour a nearby foreman told me that if you add it all up, and work out the time it takes to do each task, there’s just under twenty person hours in every unit produced at this factory, which is among the most advanced in the world.

Twenty years of Hydropool’s own research and development and production knowledge have streamlined their spa unit manufacturing process to create the best possible hydro therapeutic experience for the home user.